Kızgın yağ ile çalışan ısı transfer sistemlerinde en sık kullanılan iki seçenek; sentetik yağlar ve mineral yağlardır. Sistemin daha yüksek performans göstermesi için tercih edilen bu iki yağın farklı avantajları ve ayrıcalıkları vardır. Bu anlamda bir ısı transfer sisteminin kusursuz çalışması için bu yağlar arasında bir karşılaştırma yapmak gerekir. Bu sistemlerin daha iyi çalışması için sentetik yağ ile madeni yağı karşılaştırmak istiyorsanız bu yazıyı okumaya devam etmelisiniz!

Sentetik yağ, mineral yağa göre daha iyi performans sunan ve kalitesiyle öne çıkan bir alternatiftir. Mineral yağın doğal kaynaklardan elde edildiği düşünüldüğünde daha avantajlı görülmektedir. Ancak durum bundan oldukça farklı. Rafine ve damıtma işlemlerine tabi tutulan sentetik yağların yapısı daha ayrıcalıklıdır. Korozyon, karbonlaşma ve aşırı sıcaklıklardan kaynaklanan dezavantajlar sentetik yağlar sayesinde ortadan kaldırılır.

Koruma ve verimlilik sağlama noktasında çok değerli olan sentetik yağların ayrıcalıklarını tek tek ele almaya ne dersiniz?

Boru Hatlarını Temizler

Mineral yağlar kullanıldığında zamanla hatlarda tortu oluşumu meydana gelmesi muhtemeldir. Ancak sentetik yağların bu tür sorunlara neden olmayacağı aşikardır. Saflığı daha mükemmel olan sentetik yağlar tortu oluşumunu engelleyerek sistemin daha temiz olmasını sağlar. Bu yüksek bir performans ile çalışmasının öncelikli sebebidir.

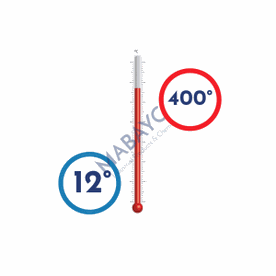

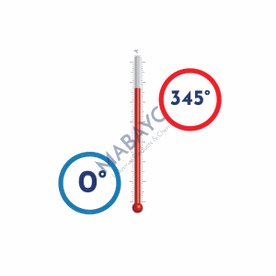

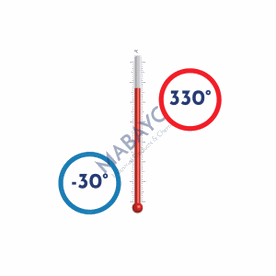

Çalışma Sıcaklığı Aralığında Mükemmel Termal Kararlılık

Mineral yağ bazlı ısı transfer yağı, parafin veya naften bazlı hidrokarbonların izomerik karışımları iken, Diphyl, Diphyl THT, Diphyl DT gibi sentetik organik ısı transfer yağları iyi tanımlanmış bileşimlere sahiptir ve moleküllerin aromatik doğası nedeniyle çok daha kararlıdır. Sentetik yağlar, mineral yağ esaslı türlere göre uygulamada kayda değer avantajlara sahiptir. Yüksek termal stabilitesi, mineral yağ bazlı HTF'ye göre yaşam beklentisini 2-3 kat artırır.

Isı transfer katsayıları, aynı koşullar altında mineral yağlar için olanlardan çok daha iyidir.

Isı Transfer Prosesi için Odaklanmış Üretim

Sentetik sıvılar olarak saf hammaddelerden yapılırken, mineral yağlar ham petrolden damıtma sişlemleri sonucunda üretilmiştir. (Bileşim partiden partiye değişkenlik gösterebilir).

İlgili çalışma koşulları her zaman optimum bir HTF (Heat Transfer Fluid – Isı Transfer Sıvısı) seçiminde rol oynar. Organik ısı transfer sıvıları genellikle aşağıdaki talepleri karşılamalıdır:

- Yüksek kaynama noktası ve dolayısıyla üst sıcaklık aralığında düşük buhar basıncı

- Oksidasyona karşı düşük hassasiyet

- Yüksek özgül ısı ve uygun ısı transfer özellikleri

- Başlangıç sıcaklığında iyi akış, toksik olmayan, düşük çevresel yük

- Kullanırken düşük güvenlik riskleri (ürünle uyumlu)

- Optimum malzeme uyumluluğu; Tesis yapımında kullanılan malzemeler üzerinde aşındırıcı etkisi yoktur

Bu bilgi ve tecrübeyi, ısı transfer sistemleri için teknik problem çözümleri aradıklarında, hiçbir yükümlülük altına girmeden müşterilerimize sunmaktan mutluluk duyuyoruz. Bu deneyim bize satış öncesi ve sonrası çeşitli hizmetler sunma şansı veriyor. Daha fazla bilgi için lütfen MABAYCO HTF ekibiyle iletişime geçin.